Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

Packaging quality is a pivotal factor in the journey of a product from manufacturer to consumer. It is the first line of defense for the product, safeguarding it against physical damage and environmental factors.

Furthermore, it plays a crucial role in customer satisfaction — poor packaging can lead to a damaged product and a tarnished brand image. Conversely, high-quality packaging can enhance the customer's perception of the brand and contribute to a positive unboxing experience.

This guide is to empower newbies who don’t know much about packaging with a clear understanding of how to evaluate packaging box quality effectively, ensuring that products are not only safe but also presented in a way that reflects the quality and care of the brand.

Packaging materials range from various types of paperboard, such as cardboard and corrugated fiberboard, to plastics, metals, and glass.

Focusing on paper-based materials, cardboard is a heavy-duty paper stock that's thicker and more durable than regular paper, while corrugated fiberboard comprises a fluted corrugated sheet and one or two flat linerboards, making it a preferred choice for shipping boxes due to its high strength and cushioning properties.

The choice of material directly impacts the overall quality of the packaging. For example, corrugated boxes are lauded for their strength and durability, which are crucial for the protection of goods during transit. The material's thickness, flute size, and the type of liners used can be tailored to meet specific requirements, such as weight capacity and resistance to compression and impacts.

When you receive the packaging box made by the manufacturer, you can make a preliminary inspection of the quality of the box based on its appearance.

Color Consistency: The colors on a packaging box should be uniform and match the brand's specifications. Inconsistencies can indicate issues with the printing process or inferior quality of inks used.

Print Quality: The print should be sharp and clear without smudging or blurring. The resolution of images and legibility of text are key indicators of good print quality.

Alignment: Proper alignment ensures that the design elements on the box are symmetrical and well-balanced. Misalignment can suggest poor quality control during the manufacturing process.

Signs of poor quality include smudging, where the ink has not been properly absorbed or has smeared during handling; blurring, where images or text lack sharpness; and misalignment, where elements of the design are not properly positioned on the box.

To ensure packaging durability, several physical tests can be conducted:

Crush Tests: These evaluate the box's ability to withstand forces that may be encountered during shipping and stacking. The Edge Crush Test (ECT) measures the stacking strength of corrugated boxes, which is a good predictor of their capacity to resist crushing when stacked.

Drop Tests: Packages are dropped from various heights to simulate handling and transportation scenarios. Observing the damage (or lack thereof) helps assess the package's ability to protect its contents during common mishaps.

Moisture Resistance: This is crucial for preventing damage from humidity or liquid spills. The Cobb sizing test, for instance, measures how much water the material can absorb in a given time, indicating its moisture resistance.

These tests are vital for simulating the conditions that packaging will face during transit and storage, helping to predict potential failure points and the overall robustness of the packaging design.

Functionality and design are as important as the physical durability of packaging. When evaluating these aspects, consider:

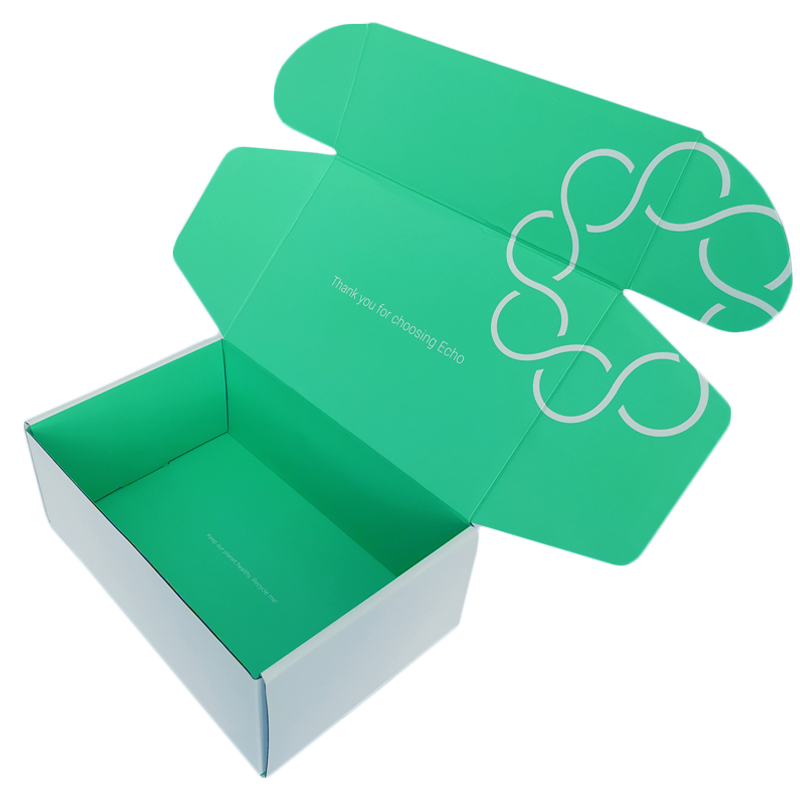

Ease of Opening: Packaging should be easy to open without tools or excessive force, which enhances the customer experience and prevents product damage from rough handling.

Resealability: If the product requires it, packaging should be able to be securely closed after opening. This feature can be important for maintaining product freshness and providing convenience for the user.

Product Protection: The design should secure the product in place, minimizing movement and the potential for damage. Adequate cushioning and the right fit are key aspects of protective design.

Unboxing Experience: The design should also consider the unboxing experience, which can have a significant impact on brand perception. Elements like easy-to-remove seals, engaging visuals, and thoughtful presentation all contribute to a memorable unboxing experience.

Prioritizing excellence in packaging is not a mere afterthought; it is an essential component of product strategy and brand reputation.

By understanding the importance of each assessment criterion and applying thorough inspection practices, businesses can ensure that their packaging meets high standards of quality.

The easiest way to get high-quality packaging boxes is to purchase them from a professional and experienced packaging box manufacturer. If you need custom packaging for your business, just contact Huaisheng Packaging.